Wood Innovations

Shifting from Plastics to Planet

This Earth Day, we’re wading into the great Planet Vs. Plastic debate. And we’re #forestproud to throw in behind Planet, just like we do all the other days of the year.

Plastics aren’t great for the planet. But when you look at the things we use every day, plastics and petroleum-based products are an essential part of our lives. From electronics, to packaging, to the windows and walls of our buildings, to our energy grid, fossil fuels and derivatives are everywhere, all the time. Wouldn’t it be great if we could replace these unsustainable products with renewable, recyclable, biodegradable, carbon-storing options that are good for the planet – and still functional for your everyday needs?

We’re working on it as a society: consumers are more likely to BYOB(ags) to the stores or ask for paper, plastic straws are on their way down, and concerns over single-use plastics are up. However, knowing what to ask for *instead* of plastics is half the battle. We’re not going to spend a lot of time talking up paper plates, paper cups, compostable packaging and cutlery, bio-based packaging, pine needle “plastic” bags, and other standbys for helping consumers move away from single-use plastics (but we will give them the shout-out they deserve!) (Actually, we may do a full blog on cool packaging innovations... * let us know if you’re interested!)

What we want to do now is look at the harder stuff – the stuff that is either so big, so ubiquitous, or so small it feels impossible to change. We’re talking about innovating the way we build buildings, the way we power our homes, and make our electronic goods. This deep dive starts with windows, goes to the walls, to concrete, to electronics, and ends with electricity itself (not a plastic, we know, but humor us here. Wood can help solve our energy needs just as it can help us innovate and design plastic out of all the things that energy powers.)

Let's start with the windows...

We're #forestproud to see transparent wood emerging as one of the most promising materials of the future. Our friends at the USDA Forest Service Forest Products Laboratory wondered if looking through trees was the view to a greener future. “Trees replacing windows—not just the frames, but the actual clear pane glass—is not a work of science fiction. It’s happening now.”

Transparent wood is created when wood from the fast-growing, low-density balsa tree is treated to a room temperature, oxidizing bath that bleaches it of nearly all visibility. The wood is then penetrated with a synthetic polymer called polyvinyl alcohol (PVA), creating a product that is virtually transparent.

The natural cellulose in its wood structure and energy-absorbing polymer filler in transparent wood means that it is far more durable and lighter than glass. It can withstand much stronger impacts than glass and, unlike glass, it bends or splinters instead of shattering.

Switching to transparent wood could prove to be cost efficient as well. It is approximately five times more thermally efficient than glass, cutting energy costs. It is made from a sustainable, renewable resource with low carbon emissions. It’s also compatible with existing industrial processing equipment, making the transition into manufacturing an easy prospect.

With all these potential benefits for consumers, manufacturing and the environment, the case for transparent wood couldn’t be…clearer.

To the walls…

If you’ve followed us for long, you know we love us some mass timber and we talk about it all the time. But what is it? Mass Timber is a catch-all term for a family of engineered wood components. As our friends over at Think Wood and Naturally Wood lay out, mass timber products are made from layers of wood, “multiple solid wood panels nailed or glued together, which provide exceptional strength and stability,” as well as offering "a structurally efficient yet low-carbon alternative to steel or concrete.” This technology is both centuries old and brand new, as the building and forest sector are constantly innovating to build taller, stronger, and faster as we meet housing demands and work to shift our buildings from a climate problem to a climate solution. Check out this cool animation below from our friends at the National Alliance of Forest Owners (NAFO) featuring some of the different mass timber product types:

Mass Timber is an essential product in our forest climate-solution toolbox that is helping us build better buildings, faster, and more sustainably. Mass timber - combined with light-frame construction - can deliver on value, longevity, speed of construction and flexibility. Mass timber helps us build faster and more efficiently, keeps carbon locked away, and allows us to provide homes that are good for people and planet.

From the walls to the concrete…

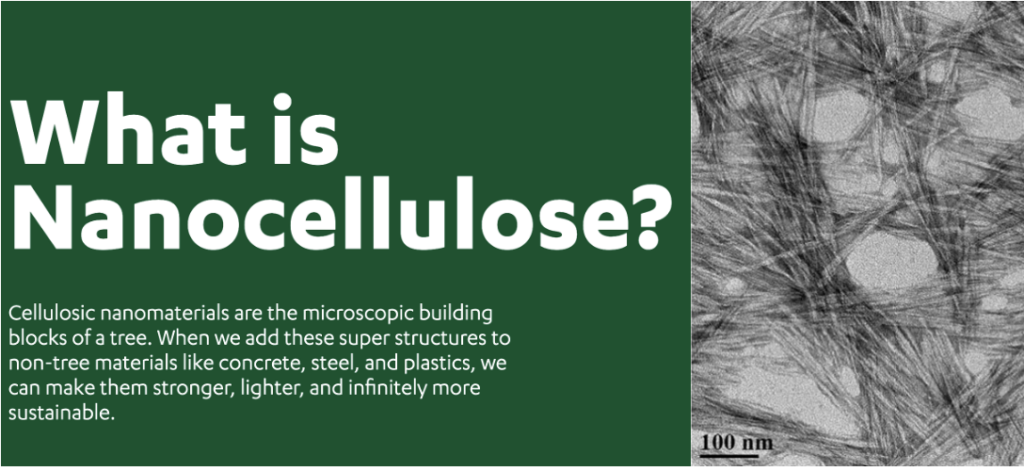

At a cellular level - one millionth the size of the head of a pin - are the microscopic building blocks of a tree. Cellulose is a basic building block of plant cells and is key to keeping plants and trees upright. (Think: those stringy bits in celery, but very, very small.) A single rod-like cellulose nanocrystal is the tiniest building block of wood. Each crystal is one hundred million times smaller than the head of a pin and can only be seen through a powerful scanning electron microscope. Nanocellulose – cellulose in its smallest microscopic form – has immense and untapped potential to create win-win solutions for people and planet.

These tiny fibers are as strong as steel, but only one-fifth the weight. Because of their structures, nanocellulose materials also have a high rate of biocompatibility - meaning they can easily be added to, or combined with, other materials. In other words, we can take the climate powers of trees and add them to non-tree materials, like concrete and steel to make them stronger and lighter.

Currently, “if concrete were a country, it would be the third largest emitter of greenhouse gases on Earth, behind only China and the United States.” The USDA Forest Service State, Private & Tribal Forestry Cooperative Forestry Wood Innovations program, Oregon State University, Siskiyou County, California, and the US Endowment teamed up to test a nanocellulose additive to concrete aimed at reducing greenhouse gas emissions. The Yreka Bridge shows how adding Cellulosic Nanocrystals to a concrete mix can reduce the amount of cement in a standard concrete mix. This reduction in cement saves a considerable amount of CO2 emissions, makes concrete lighter and more durable - and it also stores carbon in the concrete.

Wood-infused concrete can help make our buildings, homes, and our built environment greener. By adding nanocellulose to concrete, it’s been proven possible to increase its strength and help shift an essential building material like concrete from being a carbon problem to a being a carbon solution.

And from concrete to electronics.

Nanocellulose – thanks to its high biocompatibility rate that we talked about – can be added to a lot more than concrete. Enter electronics and electronic parts. We rely on electronic parts pretty much in every moment of our lives. And you guessed it, we can add wood and make these things greener, less emissions-heavy, and help turn even the tiniest bit into a carbon-storing component.

“UW–Madison engineers and collaborators constructed a functional microwave amplifier circuit — a common piece of electronics used in wireless communications — on a flexible substrate made of wood fiber. Wood-based nanomaterials can be used to make electronic components like this one pictured, computer chips, car panels, replacement tendons, car tires, and coatings that keep food fresh longer.”

Electronics can grow on trees thanks to nanocellulose paper semiconductors. Osaka University researchers, in collaboration with The University of Tokyo, Kyushu University, and Okayama University, have developed a nanocellulose paper semiconductor that provides both nano−micro−macro trans-scale designability of the 3D structures and wide tunability of the electrical properties”. This innovation has been tested and modeled and “examples of successful applications showed nanopaper semiconductor sensors incorporated into wearable devices to detect exhaled moisture breaking through facemasks and moisture on the skin. The nanopaper semiconductor was also used as an electrode in a glucose biofuel cell and the energy generated lit a small bulb.” Curious to dig into more ways that wood is adding versatility and expanding the potential in the world of electronics? Here’s a great place to start reading. (Bonus: this article talks more about wooden satellites – yes, you read that right.)

And (last but not least) electronics to electricity itself.

Bioenergy has entered the building. Literally. We know it’s not plastic, but it sure is fossil fuels heavy. So humor us on this. While we've long used wood for fuel, this innovative iteration of domestic bioenergy sourced from woody byproducts scales up to meet our modern energy demands. Domestic wood bioenergy and biofuels are reshaping our energy landscape, deriving energy from sustainable wood byproducts and reducing our carbon footprint. From wood chips to pellets, these byproducts fuel biomass boiler systems, offering cleaner alternatives to fossil fuels. We're effectively turning waste into watts, powering our homes and cities with renewable energy. Check out the video below from the Wood Innovations Program within Forest Service State, Private & Tribal Forestry Cooperative Forestry on how a Vermont school is using domestic wood energy to power its energy needs. In addition to using domestic wood energy, areas of the country like Vermont and the Northern Forest are also using local wood pellets and chips in automated systems to heat homes, schools, and businesses that in turn support sustainable forestry practices. Transitioning to wood from heating with oil or propane can reduce carbon footprints by 50% and make efficient use of wood waste and this renewable resource. This is just one example of the many ways that organizations and communities in Vermont and the rest of the USA are using domestic wood energy to reduce their carbon footprint and their waste footprint at the same time.

Woody byproducts are the backbone of this renewable bioenergy, supporting local economies, reducing fossil fuel dependency, and maintaining forests in a sustainable cycle. It's a win-win-win. This renewable source not only powers our homes and industries but also fosters healthier forests. Bioenergy is a game-changer, steering us towards a greener, renewable, and sustainable energy future.

As we embrace the shift towards biobased, renewable, sustainable products and transition away from fossil fuels and plastics, it’s more important than ever to manage our forests to meet the needs of today and of tomorrow.

Forests are intricate ecosystems. Through sustainable forest management practices, foresters and other natural resource professionals ensure forests continue to delicately balance the needs of society for biodiversity, carbon storage, timber production, clean air, clean water, and quality of life essentials.

In forestry, sustainability isn't just a buzzword; it's a crucial aspect of balancing and maintaining forests and all the great things they do for people and planet. By implementing sustainable forestry practices, we're not only protecting wildlife habitats, delivering essential products, and needed innovations but also mitigating the impacts of climate change. Managing forests responsibly reduces our carbon footprint, supports a thriving bio-based economy, and ensures a stable supply of wood-based products.

We hope you read all the links you opened in new tabs, take a deep dive into the world of wood innovations, and are newly inspired to choose wood. This Earth Day and every day, consumer choices and forest management actions directly impact the Planet vs Plastics debate facing our future consumer choices, our forests, and our ability to deliver, sustain, and scale forest-climate solutions like the innovations featured here.